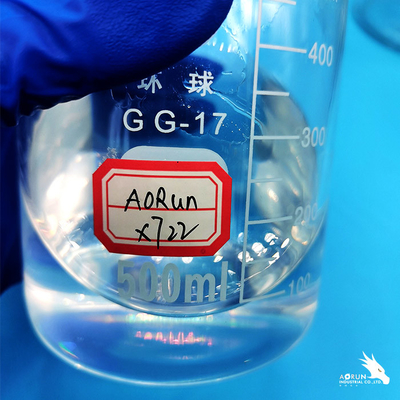

Features:

1.Can be cured at room temperature or by heat curing,

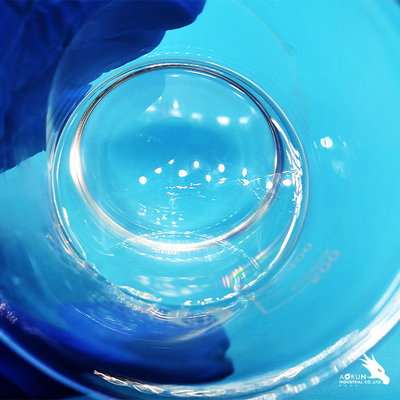

2.Can automatic antifoaming

3.Can automatic leveling

4.No bubbles

5.Good transparency and excellent surface gloss

6.Can polish after drying

7.High hardness

8.With high gloss as a mirror

Application:

Aorun X722 can be widely used for drops ofglue signscardscraftslighting photo frame, lamp potting and mold filling, etc.

For Casting crafts, jewelry, tray, coaster; Wood table top coating, tumbler coating; Wall art print and so on.

Specification:

| Items |

Units/conditions |

Technical Data

|

| Viscosity |

Shore-D |

80-85 |

| Volume resistivity |

25℃/ Ω./ cm |

4.3x1015 |

| Surface resistivity |

25℃/ Ω. |

2.6x1014 |

| Dielectric strength |

25℃ KV/MM |

25 |

| Coefficient of linear expansion |

CM/K |

<6.1x10-5 |

| Glass transition temperature |

℃ |

>90 |

| Temperature resistant |

℃ |

-60~120 |

The above performance data is typical data measured in a laboratory environment

with a temperature of 25°C and a humidity of 70%. It is for customer reference only

How to do:

MEASURING

With gloves on, pour equal amounts of resin and hardener into a mixing cup. And then pouring the mixture into another clean mixing cup to make sure you are mixing it well.

TIP - Mix up a little more than you think you'll need because you want to completely cover your work in one shot and not have to mix more later.

MIXING

Stir really well for at least 3 minutes. Scrape the sides and the bottom to make sure you're being thorough (unmixed material will leave you with sticky spots that just won't cure). Once you put the resin and hardener together, you'll have about 40 minutes of working time before the resin thickens and cures.

POURING

After making sure your piece is level, go ahead and pour AmazingResin over your work. Don't be scared! It'll start to level on its own, and you can spread it around into place. Let the resin run over the edges and then just use a brush to tidy it up. You'll notice bubbles will begin to rise to the surface. Many of these will pop on their own, but you can also pop them by torch.

TIP - Wooden panels work best for large pieces rather than canvas because they won't sag under the weight of the resin.

WAIT AmazingResin needs to sit for several hours in a dust-free space while it cures. In about 8 hours it will be tacky but you will be able to pour a second coat if necessary. In about 12 hours it will be dry to the touch, and within 24 hours it will be 95% cured. It will be fully cured within 72 hours.CLEAN UP - To reuse your mixing tools, wipe them down with a paper towel before the resin dries.

Note:

1. This product is a special large pouring glue for river tables. It will dry slowly in the production of thin layers

2. low temperature will lead to slow curing or even stop curing, low temperature environment application using high transparent low temperature curing adhesive

3. the bonding surface should be dust removal, oil removal, keep the surface clean and dry

4. the construction proportion must be accurate, improper proportion will lead to the colloid does not cure or cure is incomplete

5. AB glue must be kept sealed and pollution-free. After taking the glue, the container cover should be tightened as soon as possible to avoid dampness

6. When stirring, try to stir gently in one direction to avoid too many bubbles. When pouring, it should also be soft and light

7. It is recommended to use a vacuum defoaming machine, which has the best effect. Flame gun or hot air gun can only eliminate the bubbles within 0.5cm of the surface

8. should be in the ventilated environment construction, construction should wear gloves, masks, protective goggles and other protective measures

9. Do not take it. If it gets into eyes or mouth by accident, rinse immediately with plenty of water and seek medical advice

10. Use with caution if allergic to resin

11. the uncured glue can be cleaned with water and acetone. The cured glue can only be removed by mechanical method. If it accidentally contacts the skin, it can be cleaned with warm water and washing powder.

How to Choose Product Model:

Aorun epoxy resin is suitable for machinery, petrochemical, vehicle, electronic products, electrical equipment, construction, decoration, special purpose and other industries, especially for special purpose and multiple purposes.

Packaging:

We offer different size of packaging, 5kg buckets and 20kg buckets are normal size. Customized

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!